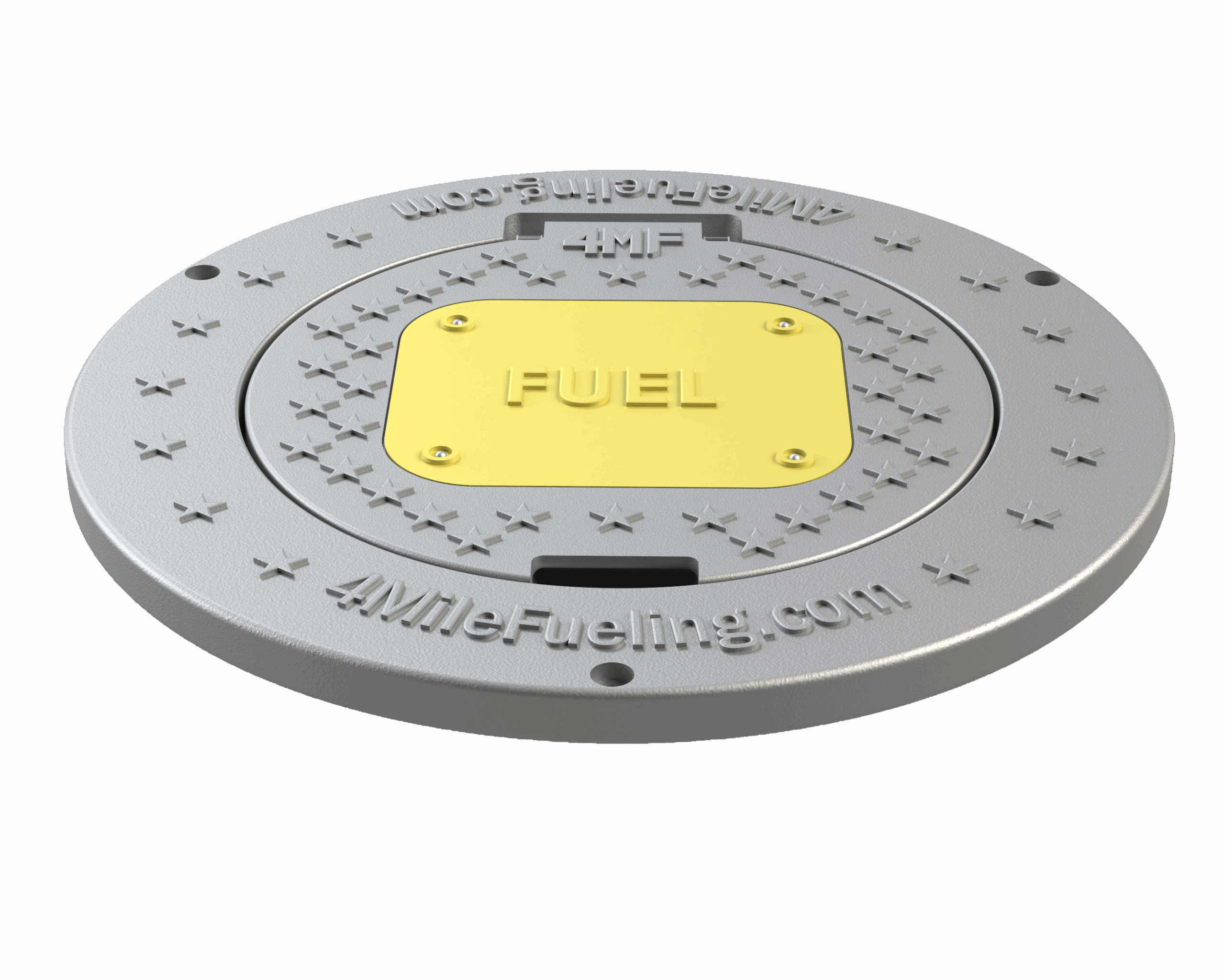

Patent-pending design meets ATA 103 standards with adjustable lay-flat capability. Built for the toughest conditions.

American-made quality meets industry-leading innovation

Proudly manufactured in the USA to the highest standards

Meets all Airlines for America lay-flat standards

Built to last and adapt to existing infrastructure

Aircraft load rated and one-hand lift compliant

Our patent-pending design integrates seamlessly with existing infrastructure while meeting the rigorious industry standards.

Airlines for America® ATA103 revisions require lay-flat hydrant pit covers by 2027.

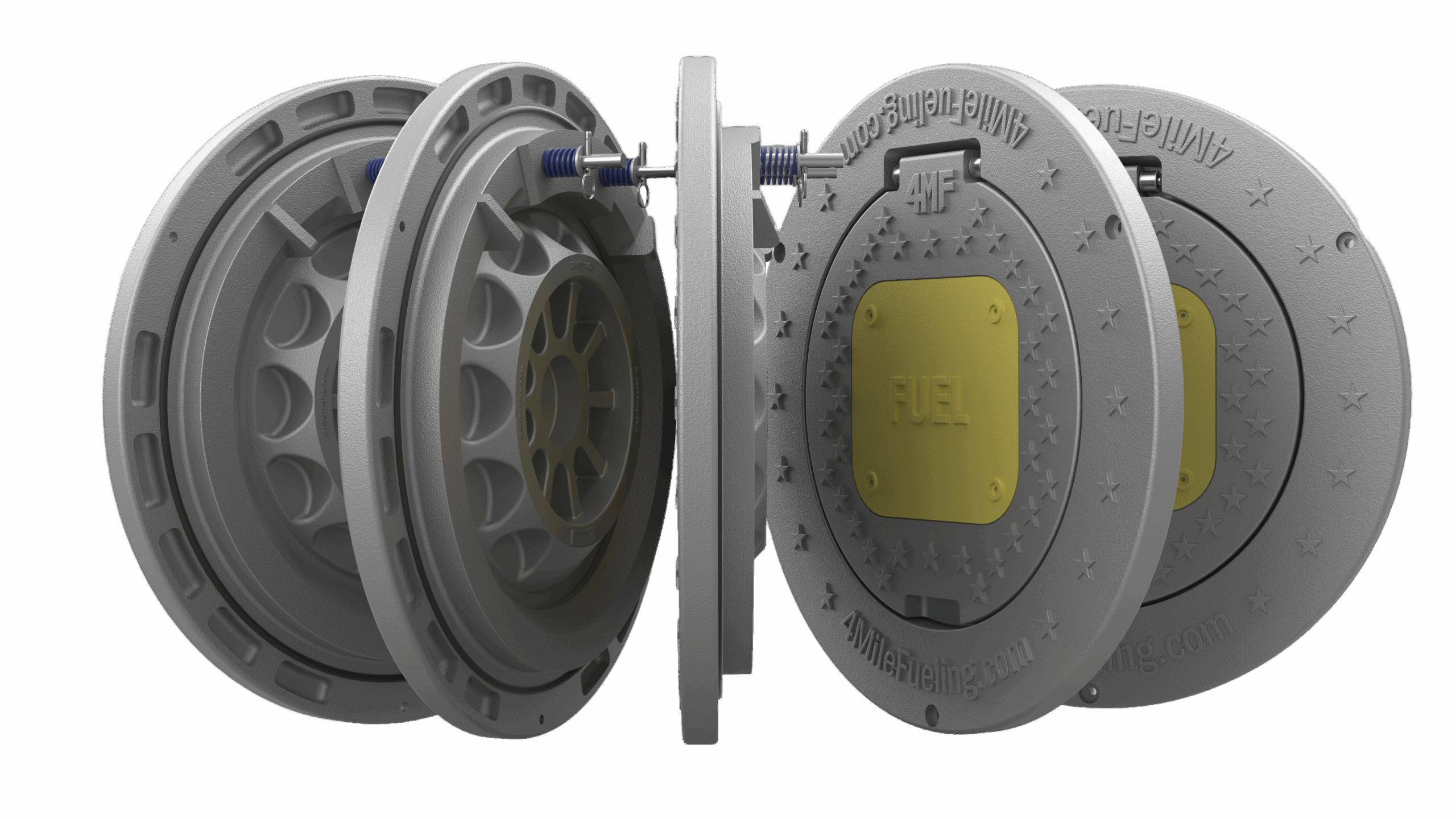

Our adjustable, cost-effective design meets those standards and can be set to lay-flat or non-lay-flat without special tools or equipment.

Our patent-pending Cover Assembly meets ATA 103 standards with a Lay-Flat Cover. It retrofits into most existing installations without costly infrastructure changes. Aircraft load-rated and tested to industry standards.

Meets ATA 103 standards with Lay-Flat Cover. It retrofits into most existing installations.

Using a Lay-Flat design avoids costly infrastructure changes. A lighter cover assembly reduces installed cost.

Adjustable to lay-flat or non-lay-flat. Retrofit into most existing installations.

Dedicated and building on 60 years of Aviation Services experience.

Central lift point provides an industry standard, one-hand access to cavity.

Certified to handle the weight and traffic of heavy carts and equipment while maintaining industry standards.

The only cover assembly with an adjustable hinge mechanism.

Load-rated and tested to industry standards, giving operators confidence it will stand up to heavy ramp traffic.

GET A CUSTOM QUOTE FOR YOUR PROJECT

Request a Quote